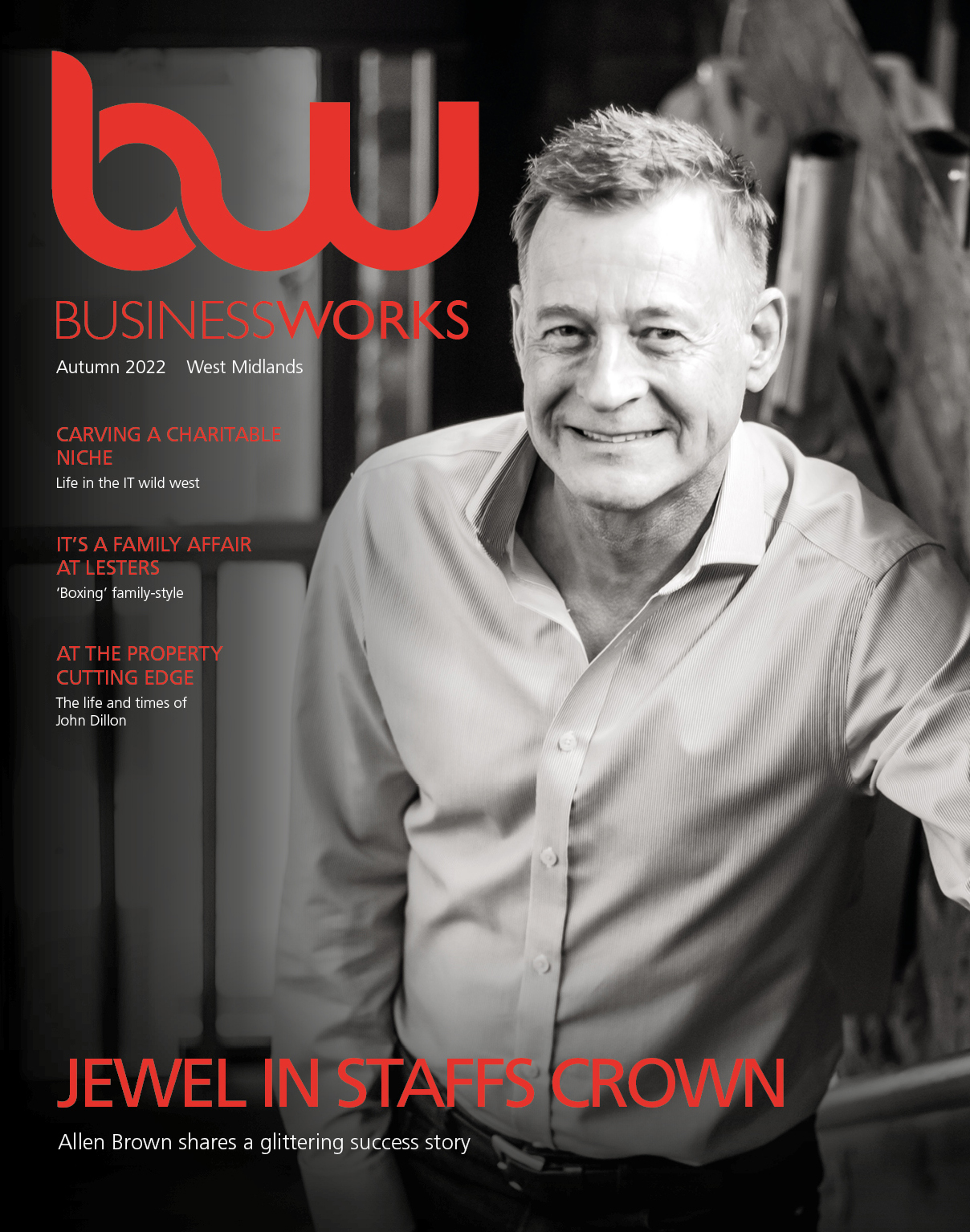

Managing Director Billy Hutchinson knows all about learning the ropes the hard way at Lesters, the family-run large packaging specialist.

“Me and my brother Scott were on a minimal wage until we were 21. I said to my dad ‘I need something else; I can’t carry on doing what I am doing’.

“His words were ‘there is not enough money to give you any more so if you want to earn more, you are going to have to go and sell more boxes’, so that is exactly what I did. I sold a million pounds worth of boxes in the first year.

“I just love business – it was anybody within a 50, 60-mile radius. I drove around knocking on doors, old school, do your research. That cemented us, both myself and my brother became directors of the business, and we went from a partnership to a limited business and incorporated us both into directorships. I would have been 21 and Scott would have been 25.”

That family ethos drilled into the two brothers from childhood has served the Burntwood-based packaging firm well ever since they took their first tentative steps around the factory floor.

Today, the Staffordshire company is a different beast and proudly lays claim to being the UK’s leading specialist in big box packaging for the aerospace, automotive, bike manufacturing, mail order and third-party logistics space. At the last count, it provides millions of corrugated boxes, large format packaging and heavy-duty cases for clients every year.

Driven by the pandemic, the last 12 months have seen a huge surge in online shopping, with sales more than doubling and 15 new staff hired to take the skilled workforce to 65 people.

It’s all a far cry from the company’s humble origins when Billy Hutchinson’s namesake and grandfather was driving around selling products in the industrial Black Country back in the 1970s.

“My grandad had a real skill for selling and that unique knack of making people want what he was selling, a life talent that certainly rubbed off on the rest of us.”

That old school mentality of relentless hard work has clearly passed down through the generations for the Hutchinson family, with brothers Scott and Billy today driving the big box packaging operations to new heights of turnover and profitability.

Meanwhile, their father Stephen, now 65, is still a familiar sight and inspirational figure at the Burntwood factory, nearly 40 years after he first founded S Lester Packing Materials as a second-hand box business based in Bloxwich.

“My dad used to work alongside my grandad and in 1983 he registered it as a partnership with my mum Tina.

“Both myself and my brother have worked in the business from the age of 12. We have worked all the way through from sweeping the floors, setting the machines, driving delivery vans, driving forklifts. We were very grounded in the fact that my dad made us learn our crafts.

“From a very young age, I was always on the factory floor. We were made to understand that if you want anything you have got to work for it. The one thing my dad wanted for both Scott and I is that if you learn your craft, all will be right.”

Today, with turnover soaring to £16.3 million it seems clear that the brothers took on board their father’s advice from an early age and immersed themselves in the Hutchinson family creed that there is no substitute for hard work.

And it’s paid off big time for Lesters, with the company offering complete, bespoke packaging solutions, varying from storing cars to luxury bathroom products, high value engineering components or even providing boxes for Premier League footballers – at champions Manchester City – to jump out of for a PR stunt.

But none of this would have been achieved without the vision and work ethic of father Stephen, the former milkman who first laid the foundations for the family firm which prides itself on being a ‘disruptive force’ in a marketplace previously dominated by just two or three big players.

Or, as Billy recalls with obvious family pride today: “My dad started off in central Walsall where Woolworths used to be. We were manufacturing on a very small scale initially, very manual machines, very labour-intensive.

“By the time I had left school, I was a fully-fledged member of the production team because I had been working Saturdays and during holidays. I had started off sweeping floors, labouring, machine setting, then production lead, then production manager.”

It was at that point that Billy once again took his father’s advice and took to the roads of the West Midlands to sell the boxes that would underpin the firm’s transformation from small scale manufacturing to the market disrupting force that is Lesters today.

“The innovation started around the early 2000s where we really started to invest. When I entered the business, the revenue would have been £300,000. The one thing I learned very quickly is you need to grow your network and surround yourself with people, attend events and build your network.

“I would go to different trade shows, go and talk to a lot of resellers as well, not always end of line users. It just started to snowball from there. We started to invest more in new technologies. We found a niche in large boxes; we bought our first large box maker in 2009 and that started to propel us because there was a new market for us which was quite niche.”

The steady progress of Lesters from small scale manufacturer to today’s thriving national force in packaging is reflected in today’s £16 million plus turnover driven by – in Billy’s words – a ‘thirst for growth’.

“We are now at the stage where we are looking for acquisitions and further growth. The 2023 budget sets out that we are going to do £24 to £25 million in terms of turnover. We are becoming a viable alternative because of our brand exposure through Russ Cockburn (West Midlands PR specialist), and through our digital transformation.

“We have got a digital marketing department here, two of the best digital marketeers in the industry who work for us.”

The rise and rise of Lesters over recent years is reflected in the buoyant client book, which now stands at around 250 to 300, embracing a vast range of different sectors and businesses.

“We work with a host of blue-chip clients from the automotive and aerospace sectors, as well as supporting food and vegetable producers, with pumpkin boxes a particularly strong area of focus for us. Our expertise also spans to bike boxes for retailers and a lot of shipping products for third party logistics companies.

“We did a campaign for Manchester City, where we provided boxes for the players to jump out of in front of fans, a press event for publicity. We have done stuff for BBC programmes and we also do a lot for charities.”

Two high-profile appointments in the shape of industry experts Mark Furman and Greg Burton as Head of Sales and Design Manager respectively have added further momentum for the Burntwood factory as the firm seeks to take advantage of the continuing surge in online shopping nationwide.

“We are very much a subscription model society now where people buy stuff on subscription online and it all has to come in a box. We grew 120 per cent through Covid as we were a critical supplier, supplying into pharmaceuticals for example.”

Further expansion post-Covid is now very much on the cards for Lesters. “We have got this site here at Mount Road in Burntwood, a new additional warehouse recently opened around the corner and a dedicated logistics and warehouse business in Nuneaton. Through the last 12 months we have recruited 15 to 16 people. The workforce is now up to 65.

“Because we have had supply chain restrictions, there have been significant material shortages and, as a result, we have become a viable alternative for some of the bigger players and we have managed to retain them after the event.

“We have bold ambitions to acquire another four businesses in the next five years, other packaging businesses, complementing businesses.”

Billy admits that Lesters had a ‘difficult’ start to 2022 with volumes falling due to Covid over-stocking and subsequent panic buying. “It was a lot quieter because we had been spoilt for the last two years with Covid – there has been a bit of normalisation.”

Nevertheless, Billy believes the future looks bright for the family firm. “We have a very strong management team around us. Myself and my brother run everything day-to-day but around us we have got a head of sales, head of marketing, head of commercial, digital, second-hand sales and, in the next few weeks, another experienced key account manager is set to join us.

“People are absolutely critical to the service we deliver and perfectly complement an investment drive that will see us soon install a TCY N6 3 colour casemaker machine to help reduce lead times and increase our capacity.”

And father Stephen, in his mid-60s, is still a significant figure in the family firm, albeit no longer involved in daily operations. “He comes in out of habit a lot of times, I would like him to play a lot more golf.”

It’s obvious that old habits – such as an ability to sell, commitment and a determination to succeed – die hard at this market-disrupting Staffordshire family firm.